Thanks to the beautiful alternation of rows of paving in North York, as well as the natural coloring of natural stones, masonry made of such stones gives the architect more opportunities of aesthetic character, than other building materials. But since it requires mainly manual labour, and highly skilled workers, which is associated with increased time and cost, its role in construction has decreased, and natural stone is replaced by other materials more suitable for mechanization of construction work. The masonry mortar, which is used to fix the masonry and distribute the load evenly, is a mixture of cement with sand and a small amount of slaked lime, glued with water to pasty consistency.

The sand must be coarse and well matched to the particle size distribution.

Table of Contents

Building stone. Stonework

Many natural stone materials belong to sedimentary rocks, the natural layering of which facilitates the production of piece stones. Granite and other volcanic rocks can be used for decorative purposes. The most important properties of building stone are durability, easy accessibility, workability, strength, homogeneity, color and texture. The requirements for building stone in North York depend on the nature of the structure.

The strength of a building stone in East York

The strength (and therefore durability) building stone in East York depends mainly on its porosity, as freezing of water in cavities leads to cracks and cracks in the stone. Water absorption of the stone, which characterizes its porosity, ranges from about 0.2% (by mass) for granite to 0.5% for marble and shale, 2% for sandstone and 4% for limestone. Destruction can also occur due to crystallization of absorbed salts, which has the same effect as freezing water. Cracking can be caused by expansion and contraction due to temperature changes. The coefficient of thermal expansion of the stone is about 0.00001/°C.

The availability of stone depends mainly on the distance of the quarry and the transportation conditions to the construction site. Freshly mined stone contains “quarry moisture”, which facilitates its processing.

Rugged stonework in York

The strength of stonework in North York depends on the stone, masonry mortar, the type of structure and the quality of work. Compressive strength (in MPa): sandstone 15-150, limestone 20-200, marble 70-150, granite 70-300. Density (in kg/m3): sandstone up to 2600, limestone up to 2700, marble 2500-2800, granite and other volcanic rocks 2600-2700.

Stone building in East York

The homogeneity of the stone is necessary so that the structure does not look motley. The colour of sedimentary materials depends on dissolved mineral salts. In some materials, such mineral salts can cause discolouration spots due to weather conditions.

Stonework in North York – is the best offer for your business!

Stoneworking in York

Natural stone building materials are used as:

- piece stone with treated surface and rubble stone.

- The masonry made of cut stone, usually made by sawing, is made with seams (filled with mortar) not exceeding 15 mm wide.

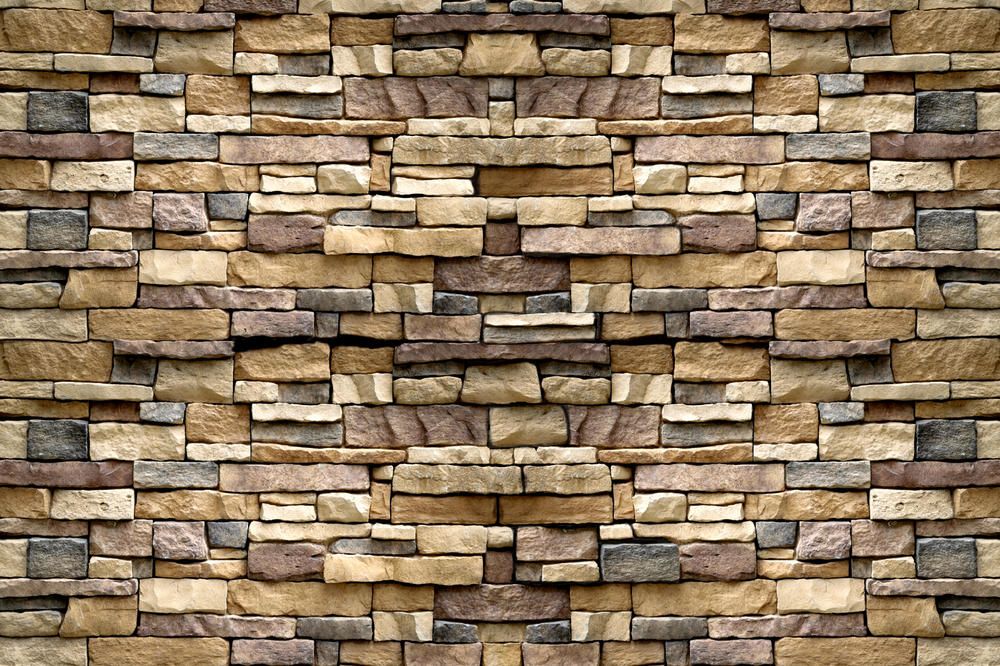

Stonework in North York is usually made in rows, but can also be made of rubble. Stone masonry is performed with joints 15 to 25 mm wide. There are three types of rubble stone: tattered (untreated), bed-like (plate-like) and cobblestone (rounded). Such stone is laid with thick seams and can be either rubble or inline. “Dry masonry” is produced without masonry mortar, but it is rarely used.

Stone masonry in York

When carrying out masonry in York it is recommended to strictly observe the following rules:

- The largest stones should be laid in the lower rows.

- Layered stones should be placed on their natural “beds”.

- To dressing the wall, it is necessary that the joints of the upper row go across the joints of the lower row and there is a correct number of “pointy” stones, i.e. stones that come out to the surface of the wall with heir end facets.

- Porous stones must be wetted before laying to prevent water from absorbing the solution.

- The gaps between the inner faces of the stones must be filled with crushed stone and mortar.

- If it is necessary to move the laid stones, they should be removed and laid again after cleaning.

- The masonry should not be done at temperatures below 0°C

- The hewn stone cladding should be placed side by side with the wall or fastened to the wall so that differences in thermal expansion and contraction are compensated.

- Since the sedimentary stones are the strongest in the direction perpendicular to the bed plane, they should be laid so that the bed plane is horizontal.

Artificial stone work in York

Standard sizes of American bricks are 206-102-62,5 mm (non-standard sizes are also allowed). English brick is slightly larger: 225-110-75 mm. According to the Canadian standard, the brick sizes are 250-120-65 mm and the average weight is 3.6 kg.

Compressive strength ranges from 15 to 150 MPa. The joint width should be within 6-12 mm for ordinary bricks and less for pressed bricks. Bricks should be placed on a full bed of mortar, and vertical joints should be filled without voids.

Depending on the finish conceived by the architect, the face seam surface can be machined into voids (under plaster), into trim (flush with the wall) or grooved to give the seam surface the shape of a roller, cove, etc. In the U.S. dressing joints (multirow system) after the first row of poke bricks are 4-7 rows of spoon bricks (with vertical joints offset), in the English – rows of poke bricks alternate with rows of spoon bricks, and in the Flemish in each row of poke bricks alternate with spoon bricks.

With a spoon dressing the surface of the wall is formed only by spoon (longitudinal narrow) facets of bricks, and the vertical joints of the row are in the middle of the bricks in the adjacent rows. The compressive strength of brickwork is 7-25 MPa, the tensile strength is 0.18-0.7 MPa. The maximum and minimum stress in a brick column with an eccentric load is calculated using the formula S = P/A (1 + 6 e/d), where P is the load, A is the cross-sectional area, e is the eccentricity of the load, and d is the side dimension in the eccentric direction.

If the height of a brick post is approximately 10 (and more) times the height of its smallest cross-sectional dimension, it should be considered as a column and the maximum permissible stress should be reduced in order to have a margin of safety against eccentric loading. In this case, to calculate the loading can use the formula S / (1 + 0.002 R2), where S – the permissible specific stress in the brickwork cube, and R – the ratio of height of the column to its smallest transverse size.

Artificial stonework in North York – practical and necessary thing for every home!

Bleaching, i.e. the appearance of whitish stains on brick walls, is caused by the deposition of salts on the surface when moisture evaporates from masonry mortar and brick. Despite the unsightly appearance, fading is harmless and can be removed with a weak hydrochloric acid solution.

Concrete stones are usually made from a mixture of 1 part of cement with 4 parts of aggregate. Up to 27% of the volume of such stone falls on voids, so the density can be only 1000-1200 kg/m3. Typical dimensions of concrete stone are 200-200-400 mm, the compressive strength is about 7 MPa (gross cross-sectional area). Ceramic hollow stones are produced in different sizes, their compressive strength is 15-30 MPa (per net cross-section area).

Concrete works in York

Concrete works in North York. Concrete is an artificial stone material consisting of pieces of natural stone (coarse aggregate) and sand (fine aggregate) bonded with cement, which is activated by water and then “grabbed”, i.e. transformed into a stonelike state by air (air cement) or in water (hydraulic cement). Cement that is blocked by water turns into a plastic mass – a binder cement dough that envelops the particles of the aggregate and fills the gaps between them. Cement entrapment is caused by hydration and crystallization of some compounds, such as silicates and calcium aluminate.

Concrete works in East York – will help you finish what you have long dreamed of!

When compiling concrete mixtures are guided by the proportion of cement, sand and stone, expressed as a ratio of volume parts, say 1:2:4. But more often indicates the ratio showing how much per one volume part of cement accounts for the volume parts of the entire aggregate, such as 1:6, and it is assumed that the aggregate will be fractionated for the densest concrete mixture. Water only needs to be taken as much as is necessary to obtain the plastic dough, as excess water reduces the quality of the concrete.

The amount of water ranges from 1:3 for the thickest (“hardest”) mixes to 1:12 for very liquid mixes. The most frequently used “plastic” mixes with water content from 1:6 to 1:9 by volume. Under technical conditions, the compressive strength of concrete can be set, and then the composition of the concrete mixture is calculated accordingly to the required strength.

The compressive strength of concrete is: 7-25 MPa, tensile strength of 0.7-1.5 MPa and shear strength of 7-10 MPa. In cases where the concrete elements of the structure must withstand significant loads on tension or bending, the concrete is reinforced.

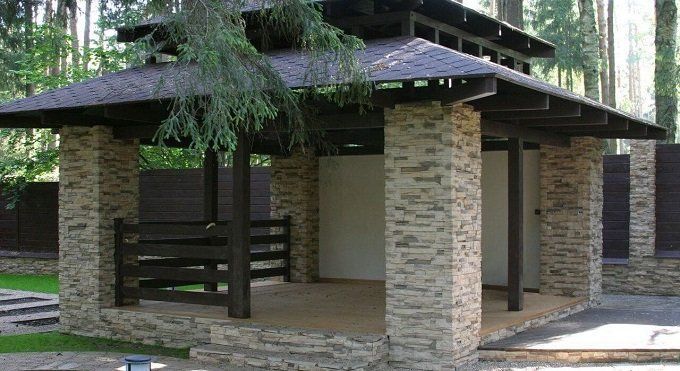

Stone buildings in North York

Stonework in York is used in the construction of such structures for which additional costs are justified, as well as in the construction of structures that in the course of normal operation are periodically exposed to moisture and air – dams, breakwater and retaining walls, bridge foundations, piers and chimneys. In warm and dry climates such as Egypt and Greece, stone structures have stood for centuries, but in countries with humid and cold climates they are more quickly destroyed by freezing water. Stonework is very compressive but has low tensile, shear and torsional strength. Therefore, Stonework with arched and enveloped ceilings such as churches and auditoriums are vulnerable to hurricanes and earthquakes if the walls are not reinforced.

Firewalls erected across large buildings to separate adjacent rooms prevent fire from spreading, and buildings made entirely of stone are fire-resistant.

Read it as well:

Award-winning Landscaping Company

CONTACT US TODAY

for a Free Estimate!

Contact us and speak with one of our service professionals to schedule a visit today!

GET A FREE QUOTE