Terrace board – purpose

Suppose you have a task to make a floor on a terrace, an open veranda, a gazebo or a stage in the open air. What building material to choose for these works. Ideal for tiles, but it is technologically difficult and therefore not rational. It is very expensive to use waterproof wood. Using classic types of wood is not durable and guaranteed to lead to repair of the floor in a few years. The solution to the problem of a material for the floor that is not afraid of moisture, while looking like a real board is a terrace board made of wood-polymer composite.

According to the characteristics of manufacturers, the terrace board is designed: For laying on the terraces, gazebos, piers, pools, any outdoor areas, baths, showers, balconies.

Unique features of the terrace board

The unique characteristics of the terrace decking can be attributed to:

- The need for additional protective coating and annual renewal of the protective layer;

- WPC board does not rot or fear water;

- It has a high-strength top layer and high load-bearing strength (500-550 kg per meter).

As we can see, the range of applications of the terrace board is quite wide, and some applications are unique.

Cost of WPC board

It is worth paying attention to the price of the terrace board. A wide range of prices for the board is determined by the following factors:

- Cheaper hollow board, more expensive full board;

- There are planks of suture and seamless laying;

- Different roughness ;

- The price also varies depending on the manufacturer.

For example, the terrace board available in Canada, costs $ 15 per meter. As we see the cheap terraced floor will not cause you any financial problems. Given the service life and ease of installation and the lack of annual maintenance, this price is quite comparable to the price of a wooden board. Especially important is the service life of the terrace board, which is 50 years.

What is the terrace board made of?

The terrace board belongs to polymer composite materials. It consists of 65±5% chopped hardwood and 35±5% polymers and additives. Often the terrace board is called WPC board, which means wood-polymer composite. As we see the wooden floor from the terrace board is a good idea.

Where is the terrace board produced?

The terrace board in Ontario is not an exotic material and quite a few production facilities are located in Canada.

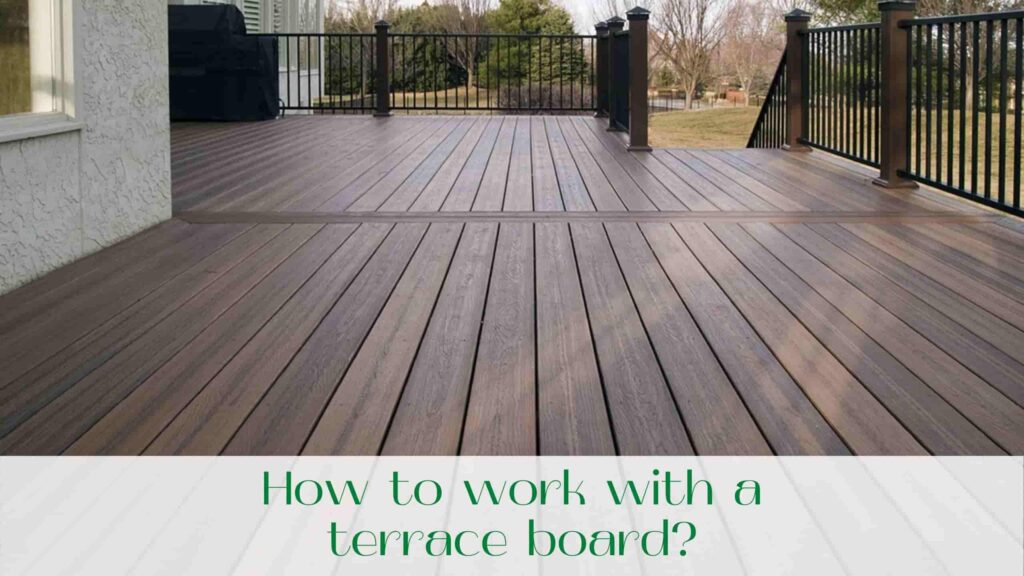

How to work with a terrace board?

There are no special tricks in working with the terrace board. The technology of its laying is similar to work with a wooden board, but the requirements for the base are somewhat simplified.

- The base of the floor should not deform either from the weather or the seasons;

- Lay a terrace board on wooden or WPC lags, which are aligned to the horizon;

- Place the terrace decking with plastic or metal concealed fixing.

- WPC boards are laid in a seamless or sutureless way.

Seamless method can be with shifting rows (in junction) with a long surface length or with whole boards. Seamless method of installation is used on the surfaces of the floor, where a constant outflow of water is needed, such as a shower. The method of installation is important when choosing a board.

- Cut the terrace board with any tool that cuts (saws) wood.

- End parts of the terrace board, if they will be visible, are closed with special plugs.

Terrace board texture

Taking into account that WPC board is sometimes called “liquid wood”, in theory, the texture of the terrace board can be any. However, manufacturers seek similarity to natural material by limiting themselves to a standard set of textures:

- For wood (of different species);

- Narrow corduroy (in a narrow strip);

- Wide corduroy (in wide stripe).

In conclusion, it should be noted that the WPC material is used to produce steps, fences, facades, railing, stairs. The terraced floor or patio floor must be made of WPC (patio board). And our company “Captain Handy” can make from the terrace board in Toronto – steps, fences, facades, railing, stairs , patio. Simply contact us or leave a request.