Outdoor decoration is important for the home. It not only gives a complete look, but also decorates the structure. Facade cladding forms a reliable sound and thermal insulation, protects the house from the negative effects of the environment. The exterior cladding extends the service life of the building and prevents destruction, strengthens the structure of the house.

Today they produce various materials for exterior decoration of house facades. You can easily select products by quality, price and appearance. When choosing a material to consider the operational properties and aesthetics.

High-quality facade materials in Toronto for exterior decoration of the walls of the house should protect the structure from wind, steam and moisture, temperature changes. The cladding should be resistant to fungi and mold, which lead to the formation of cracks in the house. In addition, it should fit harmoniously into the landscape of the site.

In this article we will consider in detail what types of cladding materials are produced today.

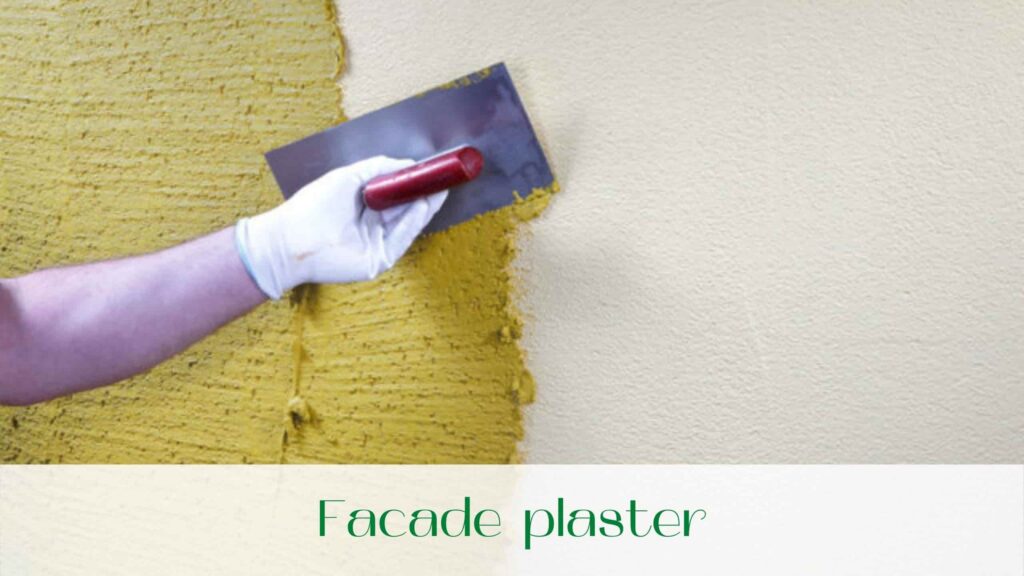

Facade plaster

Plaster is a usual and common finishing material, which is used for work both inside and outside the house. Decorative plaster for facade in Toronto is distinguished by its availability and low cost, a wide range of colors and textures, resistance to damp. With the right technology of installation of the material well tolerate temperature fluctuations, does not burst in the cold and does not crumble over time. Easy application of plaster will perform the installation of their own hands without involving specialists.

There are several types of plaster, including mineral, acrylic, silicate and silicone. Let’s look at the specifics of each:

- Mineral plaster is the most common type of plaster with a low price and a wide range of colors. This material is characterized by its resistance to microorganisms, moisture and ultraviolet. It does not burn, but has low elasticity. Therefore, when the house is shrunk, the finish cracks;

- Acrylic plaster is more elastic and can easily withstand shrinkage, so it is quite suitable for a wooden house. It is distinguished by its durability and long service life, resistance to frost and moisture. However, the walls with this finish quickly get dirty. Acrylic plaster is easily inflammable, so the material can not be used for walls insulated with mineral wool;

- Silicate plaster – the most durable material, finishing which will last 20-30 years. During this time, it retains its appearance and performance qualities. Walls with such finishing are practically not dirty and are resistant to moisture. Silicate plaster does not break when shrinking the house, but requires certain skills in installation, as the material to be applied very quickly. In addition, it has a limited choice of colors;

- Silicone plaster is a wear-resistant material that will last for several decades. It is non-polluting, easy to apply and has no problems with shrinkage and moisture. Experts recommend this particular material for the exterior decoration of the house. The only disadvantage of silicone plaster is its high cost.

Regardless of the view, to keep the plaster long, you need to thoroughly prepare the walls. The surface is cleaned from old finishes, dirt and dust. Wooden walls are polished, necessarily treated with antiseptics and fire retardants, insulated.

Facade materials – Siding

Siding is a modern material that has gained popularity due to its availability and low price, easy installation and aesthetic appearance. Panels are easy to install with your own hands. They look neat and harmonious. Besides, they are universal. Siding is used to decorate buildings of any material. It is easy to wash, effectively protects the structure from the negative effects of the environment.

Today, the following types of siding are produced:

- Vinyl siding in Toronto is a separate panel of PVC, which imitate stone, brick or wood. It does not dry up and does not rot, endures temperature changes, is resistant to frost and ultraviolet. Vinyl panels are lightweight, so they do not give a strong load on the walls and foundation of the house;

- Wooden siding in Ontario is made from dried and treated wood. It is the most environmentally friendly and safe material, so it is suitable for finishing the house from log or timber. It looks neat and harmonious and keeps warm well. However, wooden siding has a high cost and requires constant care. Treatment with antiseptics, flame retardants and various paintwork materials is done every 3-7 years, depending on the type of products. Without the necessary care wooden siding will not serve long;

- Metal siding in Toronto is made of aluminum and steel. It is resistant to temperature changes and easy to clean, has a high strength and durability. However, the metal is not resistant to moisture and when the top layer of the panels is damaged, corrosion begins. In addition, metal siding increases the weight of the house and increases the load on the foundation.

Before installing siding in Toronto, the wall surfaces are prepared and the old finish, dirt and dust are removed. Then install a crate of bars, which are located at a distance of 0.5 m from each other. The purlin will ensure proper ventilation. In addition, between the bars put insulation, waterproofing and vapor barrier films. Already on top of the purlin fasten the panel.

Facade materials – Sandwich panels

Such panels are two or three dense layers, between which the insulation is laid. This is an aesthetically appealing material with a wide range of colors. It is lightweight, fireproof and durable, resistant to moisture and can be repaired. If one of the panels is damaged, you do not need to update the cladding completely, it is enough to replace the damaged panel.

As a heater in sandwich panels use mineral wool, polystyrene foam or glass fiber. The panels themselves are also made from different materials, among which:

- Galvanized steel – the most common option due to the affordable price and ease of installation. This is a durable product, which, however, over time, burns out, darkens and loses its original color;

- Aluminum and zinc alloy – a more expensive material, which is characterized by increased resistance to mechanical damage and high anti-corrosion qualities;

- The plasterboard is environmentally friendly and safe. It is a strong and plastic material with light weight. Resistant to fire;

- Plastisol and Purul are reliable and durable materials that are resistant to mechanical damage, corrosion and ultraviolet. Plastic products are easy to process and install;

- Polyester – economical material with high quality, which is suitable for any climate. It is resistant to temperature drops, frost, UV and moisture. It is not afraid of mechanical damage.

The big plus of sandwich panels is that they are already with insulation. This allows you to save on heating and home insulation. The material is distinguished by its easy installation in a short time. However, during installation, it is important to comply with technology and standards, otherwise the material will quickly become unusable, and the insulating properties will be greatly reduced. During installation, you can not use a sealing tape. Otherwise, the connection points of the panels will freeze.

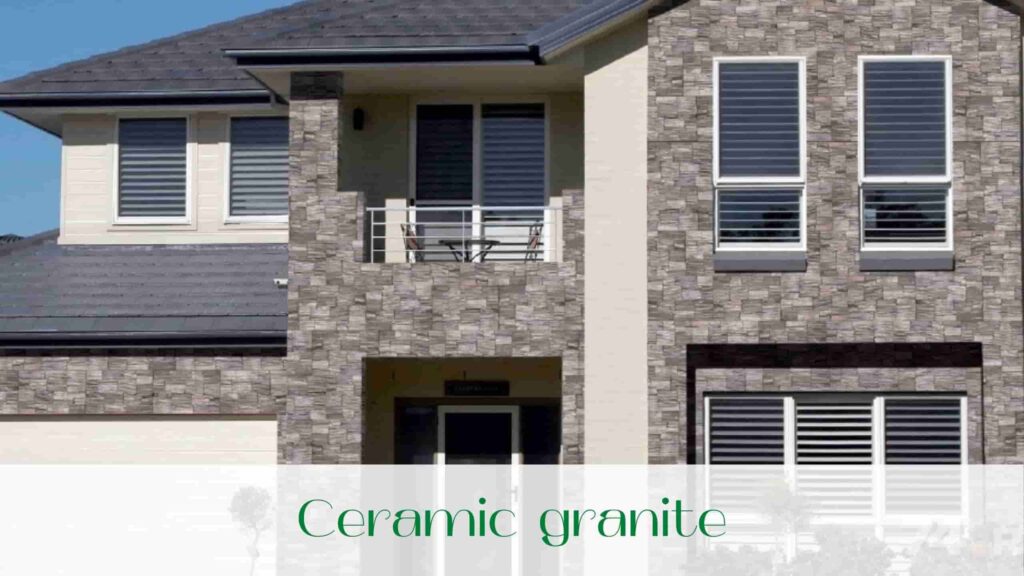

Facade materials – Ceramic granite

Decorative material with a wide range of colors and textures can make the house original and unique. Porcelain stoneware is characterized by strength, wear resistance and durability. It is resistant to moisture and low temperatures, abrasion and mechanical damage. The material does not burn or lose color during use. Ceramic granite will provide a reliable and high-quality finish, will embody the most daring and interesting design solutions.

Produced the following types of porcelain stoneware:

- Matt products have a natural look and high performance;

- Flax or satin material has a surface with a noble waxy luster. This shine is obtained through the use of mineral salts in the manufacture of the material. Cucumber porcelain stoneware is similar in properties to matte, but is more expensive;

- Glazed porcelain stoneware in appearance similar to ceramic tiles, but it is much stronger and more reliable;

- The polished products have a rich sparkling color. This material is used for both interior and exterior decoration;

- Semi-polished porcelain tiles combine shiny and matt areas;

- Structured products have a rich texture. Structured porcelain stoneware is both embossed and patterned. They produce materials with a texture that imitates wood or stone;

- Mosaic porcelain tile transforms and makes the building luxurious. However, this type of materials is characterized by complex and time-consuming installation.

Among the disadvantages of the material, we note the specific and complex installation. Ceramic granite attached to a special adhesive or metal frame. In no case should not install the material on the cement mortar, as it will fall off in the cold.

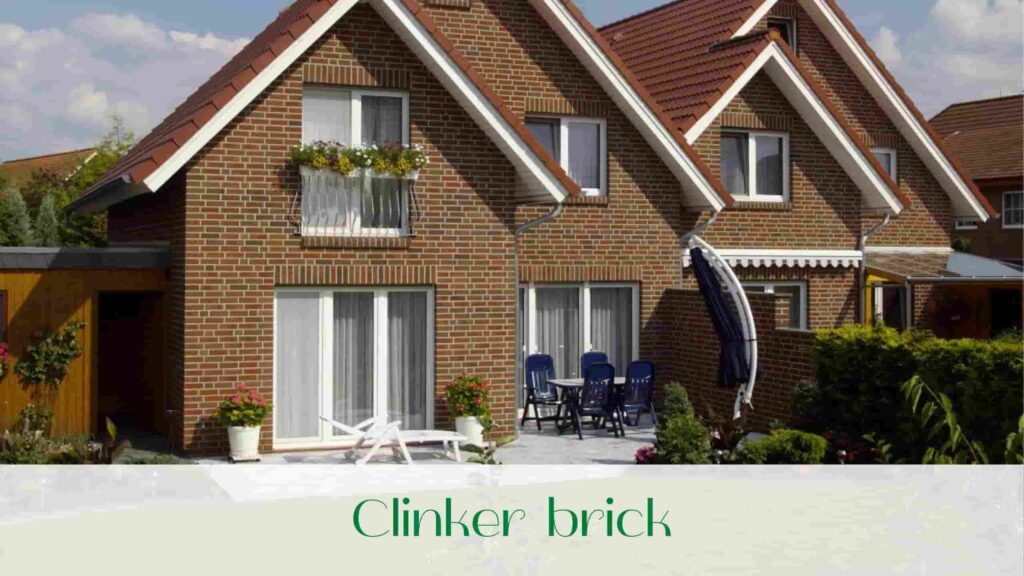

Facade materials – Clinker brick

Clinker brick looks like a building brick. It is a natural material, which is made of clay and natural dyes. They produce bricks for facade and sidewalk. In addition, there are clinker tiles, which are also made from natural raw materials. Today you will find hundreds of types of material with different textures and colors. The surface can be embossed, grooved, glossy, matt or glazed.

Clinker materials do not absorb water and are easy to wash. They are durable and durable, resistant to household cleaning chemicals. Tiles and bricks tolerate frost, aggressive UV exposure and temperature changes. However, the materials are expensive and difficult to install.

Other facade materials in Toronto

Sometimes natural or artificial stone is used for exterior decoration of the house. This is an expensive cladding, but reliable and durable. Artificial products are cheaper and more diverse. Natural stones are used for finishing marble and granite, basalt and sandstone, shale and other types.

Another type of facade finishing in Toronto is metal cassette. Such cladding is used for ventilated facades. This is a reliable and durable material, resistant to mechanical stress and negative environmental impact. On the market there is a wide range of colors, textures and sizes. The only disadvantage of metal cassettes is the high cost.

Whichever finishing material you would not choose, it is important to properly perform the installation. Non-compliance with building codes will lead to rapid destruction of the cladding. Facade will lose its previous appearance. In addition, on the walls of the house may appear cracks, and the structure will deteriorate. To avoid such problems, contact the professionals!

The experts of the company “Captain Handy” will select quality fecade materials in Ontario, reliably and quickly perform the work on the facade finishing in Ontario. We repair houses and verandas, conduct and connect engineering networks on the land plot, make internal and external finishing “turnkey”!

Read our blog!